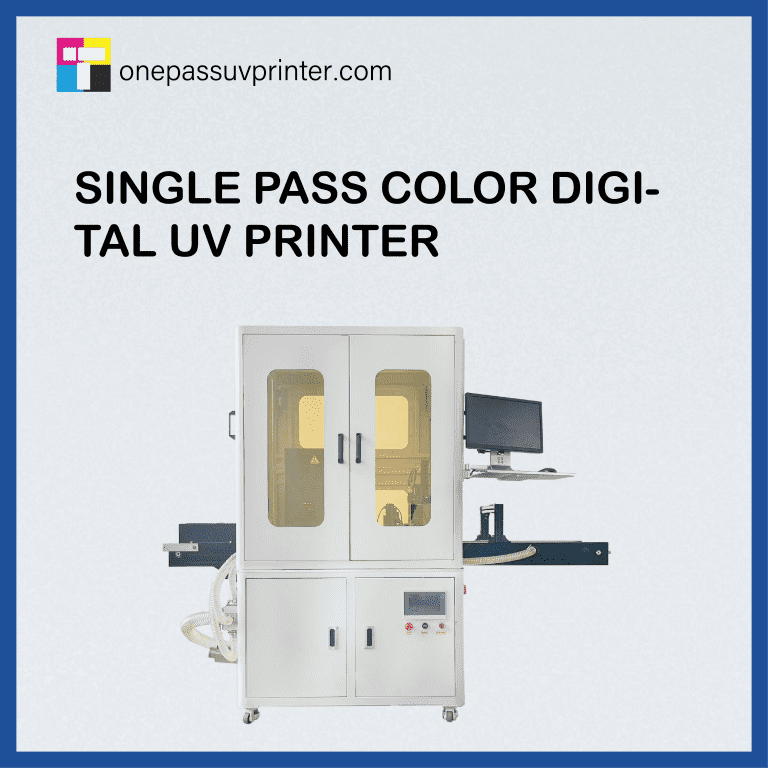

Packaging print domain is being reshaped by pioneering one-pass UV developments. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. Using UV curing to set inks instantly, single-pass UV removes extended drying cycles and repeat runs, cutting costs and turnaround.One of the key benefits of this technology is its ability to produce vibrant and long-lasting prints on a wide range of substrates, including plastics, metals, and textiles. The fine resolution possible with one-pass UV produces crisp detail in images and text, appropriate for packaging, signage, and adverts. In addition, the technology’s reduced energy use relative to conventional printing fosters a more sustainable manufacturing workflow.

Packaging print domain is being reshaped by pioneering one-pass UV developments. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. Using UV curing to set inks instantly, single-pass UV removes extended drying cycles and repeat runs, cutting costs and turnaround.One of the key benefits of this technology is its ability to produce vibrant and long-lasting prints on a wide range of substrates, including plastics, metals, and textiles. The fine resolution possible with one-pass UV produces crisp detail in images and text, appropriate for packaging, signage, and adverts. In addition, the technology’s reduced energy use relative to conventional printing fosters a more sustainable manufacturing workflow. The integration of one-pass UV technology has opened up new possibilities for businesses seeking to enhance their printing operations.

The integration of one-pass UV technology has opened up new possibilities for businesses seeking to enhance their printing operations. Single-Pass UV Advancements

High-throughput digital printing persistently aims for efficiency. Traditionally, this involves multiple passes of ink, leading to increased production times and potential for misalignment. Yet Single-Pass UV’s debut is redefining the industry. Through single-pass UV curing, inks are fixed instantly, providing impressive speed and precision advances.Single-Pass UV creates striking color fidelity with high clarity and detailed richness. This makes it ideal for demanding applications such as high-volume packaging, billboards, promotional materials, where speed and visual impact are paramount. As advances continue, single-pass UV promises more revolutionary gains toward fast, flexible, and cost-efficient printing.

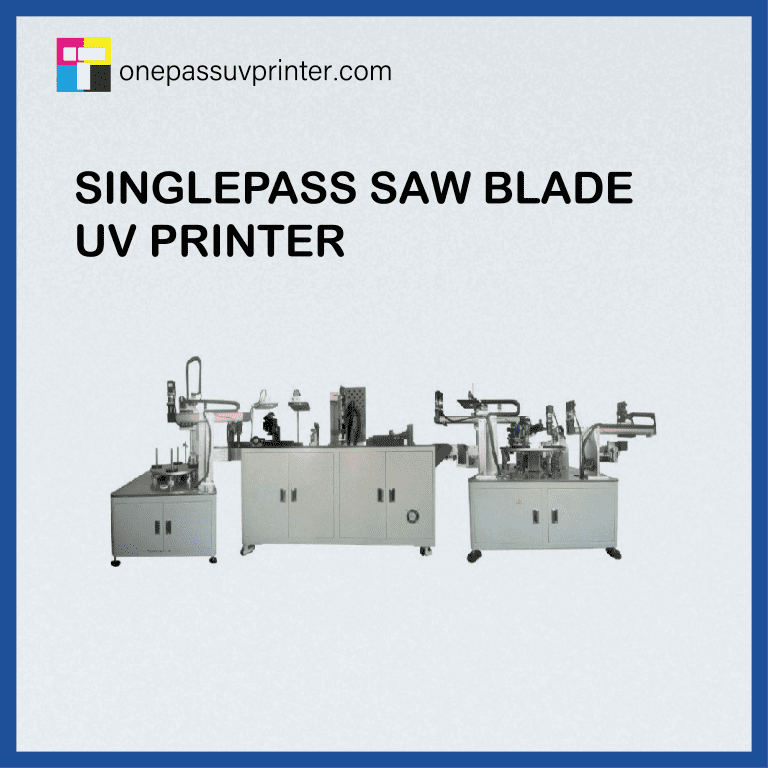

Single-Pass UV Printers: Speed Meets Accuracy

In the dynamic realm of printing technology, single-pass UV printers have emerged as a game-changer, redefining speed, precision, and efficiency. These innovative devices employ ultraviolet (UV) curing technology to instantly harden inks, enabling unparalleled production rates. By executing multiple colors in one pass, these printers produce exceptional clarity and vibrant color profiles. From tailored product print to extensive commercial printing, these systems adapt to many uses, empowering businesses amid increasing demand.Upgrade Your Printing Journey

Expect to be impressed by the single-pass UV printer — a strong solution transforming industry norms. This clever device leverages UV light to fix inks in one pass, attaining remarkable quality and resolution.- Benefit from bright tones with exceptional detail

- Improve turnaround with rapid printing capacity

- Extend creative potential with wide material compatibility

High-Throughput UV Printing: Delivering Unmatched Efficiency

UV printing has remade the graphics field via speed, exactness, and bold color output. High-speed UV elevates those strengths further, enabling exceptional production efficiency. The approach uses dedicated printers engineered to produce high-res images at very high speeds. With instant UV cure and limited drying, accelerated UV printing refines operations for fulfilling high-pressure orders. The perks of fast UV printing include broader value beyond mere operational efficiency. It provides superior print quality, long-term durability, and broad application possibilities. From packaging and large-format banners to labeling and promotional signage, rapid UV printing alters business processes to support innovation and market leadership.

Rapid Printing: The Ultimate Solution for Fast Turnaround Times

In a time-driven market, speed is crucial. For printing, businesses require fast, efficient solutions. Enter One-Pass Print. This method produces prints in one pass, cutting out multiple runs and accelerating processing time. One-Pass Print enables greatly faster turnarounds, freeing staff and resources. Consequently, companies small and large gain from One-Pass Print benefits. From promotional prints to required documents, it supports immediate printing with no trade-offs.Quality and Velocity Combined in Single-Pass UV

Within today’s industrial landscape, efficiency dominates. Producers need systems that preserve quality and sustain speed. Single-pass UV appears as a breakthrough merging fine inspection with instant curing. This process employs UV light to set inks and coatings instantly, achieving durable colorful finishes and minimizing cycle time. Inherent accuracy in single-pass UV yields impeccable products that meet high-quality thresholds. Benefits expand beyond improved speed and fidelity. Single-Pass UV lowers waste through instant curing, supporting eco-friendlier production.- Moreover, single-pass UV’s flexibility allows use across many sectors, from packaging and print to electronics fabrication.

Innovating Digital Printing with High-Speed UV

The print sector keeps evolving, propelled by ongoing needs for speed, accuracy, and fresh solutions. Rapid UV tech has surfaced as a transformative force combining these crucial elements. UV printing relies on ultraviolet curing to set inks immediately, removing long dry cycles and expanding printer capabilities. Fast UV cure produces high print rates, cutting production time and elevating operational efficiency. Furthermore, UV inks possess exceptional durability and resistance to fading, one pass printer scratching, and water damage, making them ideal for a wide range of applications. From colorful signage to durable product packaging, fast UV printing is redefining printing standards.- Benefits

Instant Output Age: One-Pass UV Technology

In speedy graphics and imaging sectors, time is a critical asset. Customers insist on fast turnarounds and businesses must deliver superior prints on request. This is the role filled by one-pass UV printers, which offer groundbreaking solutions for modern printing. These advanced machines utilize ultraviolet (UV) inks that instantly cure upon exposure to light, eliminating the need for time-consuming drying processes. Result: immediate prints showcasing lively colors and robust finishes. Consequently, single-pass UV printers are used in varied industrial applications. From retail/e-commerce/marketing to photography/fine art/manufacturing, businesses are embracing the benefits of instant printing. Use cases range from custom product creation to bespoke signage and striking marketing materials. Benefits extend past quickness and efficiency gains. One-pass UV systems supply precise color reproduction, high-resolution output, and versatile substrate handling for complex projects.- Moreover, one-pass UV supports greener production by eliminating solvent use and VOCs.

- Ultimately, immediate-printing is upon us; single-pass UV’s speed, versatility, and quality are redefining printing and enabling greater efficiency.

Transform Your Workflow with Single-Pass UV

Refine operations and achieve new efficiency gains with a single-pass UV printer. This cutting-edge technology enables you to print vibrant, high-resolution images directly onto a variety of substrates in a single pass, eliminating the need for tedious layers.- Obtain superior speed and shorten manufacturing time.

- Enhance production output with reduced turnaround.

- Benefit from the precision and durability of UV ink for lasting, vibrant results.

Advantages of Single-Pass UV for Impactful Printing

Single-pass UV printing represents a radical shift for high-impact print applications. Using UV to cure ink instantly, this method brings significant advantages beyond traditional processes. Chiefly, single-pass UV provides excellent image fidelity via rich colors and clear detail. By removing drying stages, the cure boosts productivity and speeds turnaround times.- Also, prints from single-pass UV deliver long-lasting resistance to fade and abrasion.

- Summing up, superior image fidelity, productivity gains, and lasting prints make single-pass UV a compelling high-impact solution.